Gas & Air Filtration Housing and Elements

ASME, PED and CRN Flanged Filter Housings

Housing Features:

Housing Features:

- Available in Carbon Steel and Stainless Steel.

- Stainless Steel construction, High-quality 304 and optional 316L, means no fouling or corrosion and long service life.

- Plenum chamber design improves drainage from the filter housing when used to coalesce liquids.

- Vents tapped 1/4″ FNPT.

- Available with F, S and A Series filter elements.

- EPDM housing seal. Other elastomers available.

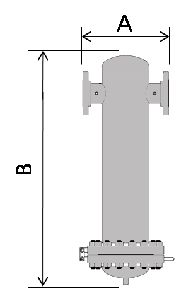

| Flanged Microfilters 1″ – 12″ | ||||||||

| Model | Capacity (scfm) at 100 psig effective working pressure nominal |

Connection Flanged | Dimensions | Number of Filter Elements | Maximun Operating Pressure |

Weight (lbs) |

||

|---|---|---|---|---|---|---|---|---|

| A | B | |||||||

| HVM FF-1-XX-# | 177 | 1″ | 10 | 16 | 1 | 232 | 24 | |

| HVM FF-1.5-XX-# | 412 | 1 1/2″ | 10 | 28 | 1 | 232 | 31 | |

| HVM FF-2.0-XX-# | 853 | 2″ | 13 | 42 | 1 | 232 | 57 | |

| HVM FF-2.5-XX-# | 1,142 | 2 1/2″ | 20 | 41 | 1 | 232 | 89 | |

| HVMFF-3.0-XX-# | 1,142 | 3″ | 35 | 52 | 1 | 232 | 352 | |

| HVM FF-4.0-XX-# | 2,560 | 4″ | 39 | 57 | 3 | 232 | 482 | |

| HVM FF-6.0-XX-# | 5,120 | 6″ | 62 | 65 | 3 | 232 | 935 | |

| HVM FF-8.0-XX-# | 8,533 | 8″ | 66 | 70 | 10 | 232 | 1,577 | |

| HVM FF-10.0-XX-# | 13,653 | 10″ | 74 | 76 | 16 | 232 | 2,037 | |

| HVM FF-12.0-XX-# | 17,066 | 12″ | 74 | 76 | 20 | 232 | 2,328 | |

| *Contact HVM for larger and custom sizes. | ||||||||

| Substitute the corresponding material type and element type where appropriate: | ||||||||

| XX – CS for Carbon Steel | ||||||||

| XX – SS for Stainless Steel | ||||||||

| # – F Series Microfilter Element | ||||||||

| # – S Series Microfilter Element | ||||||||

| # – A Series Activated Carbon | ||||||||

Carbon Steel & Stainless Steel Filter Housings

Housing Features:

Victaulic Coupling with double ‘O’ ring and bayonet for positively locating the element.

Victaulic Coupling with double ‘O’ ring and bayonet for positively locating the element.- The ‘O’ ring eliminates possibility of particle or liquid bypass therefore insuring filtration integrity.

- Stainless Steel construction, High-quality 304 and optional 316L, means no fouling or corrosion and long service life.

- Plenum chamber design improves drainage from the filter housing when used to coalesce liquids.

- Vents tapped 1/4″ FNPT.

- Available with F, S and A Series filter elements.

- EPDM housing seal. Other elastomers available.

- Also Available as connection type: BSP, NPT, and Socket Weld.

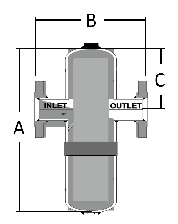

| Threaded Coalescing/Particulate Filters 1/2″ – 3″ | ||||||

| Model | Capacity (scfm) at 100 psig |

Connection Flanged | Dimensions | Maximun Working Pressure (psig) | ||

|---|---|---|---|---|---|---|

| A | B | C | ||||

| HVM-FVT-0.5-XX-# | 88 | 1/2″ | 11.8 | 8.3 | 3.9 | 232 |

| HVM-FVT-0.75-XX-# | 118 | 3/4″ | 13.2 | 10 | 4.5 | 232 |

| HVM-FVT-1.0-XX-# | 171 | 1″ | 15.2 | 10 | 4.6 | 232 |

| HVM-FVT-1.5-XX-# | 294 | 1 1/2″ | 15.2 | 10.01 | 4.6 | 232 |

| HVM-FVT-2.0-XX-# | 459 | 2 | 21.7 | 11.6 | 5.1 | 232 |

| HVM-FVT-2.0H-XX-# | 677 | 2 | 34 | 13.4 | 5.1 | 232 |

| HVM-FVT-2.5-XX-# | 853 | 2 1/2″ | 34 | 15.2 | 5.1 | 232 |

| HVM-FVT-3.0-XX-# | 1,148 | 3″ | 45 | 15.2 | 5.1 | 232 |

| Pressure Conversion Factors | ||||||||||||||||||

| Pressure (psig) | 5 | 10 | 14 | 28 | 43 | 57 | 71 | 86 | 100 | 114 | 128 | 148 | 157 | 171 | 186 | 200 | 217 | 232 |

| Correction Factor | 0.08 | 0.18 | 0.25 | 0.38 | 0.50 | 0.63 | 0.75 | 0.88 | 1 | 1.13 | 1.25 | 1.38 | 1.5 | 1.63 | 1.75 | 1.88 | 2 | 2.13 |

For maximum flow rate, multiply model flow rate show in the table by correction factor corresponding to the working pressure.

Victaulic Coupling with double ‘O’ ring and bayonet for positively locating the element.

Victaulic Coupling with double ‘O’ ring and bayonet for positively locating the element.