Gas Dehydration

At the rig, natural gases are nearly always saturated with water. When water-saturated natural gas flows in a pipeline the following problems can occur:

- Water can collect in pipelines and increase the pressure drop and/or cause slug flow.

- Water can freeze and/or form solid hydrates, consequently reducing the gas flow or plugging the line.

- Acid gases (H2S & CO2) dissolve in free water and will cause severe corrosion.

Ideally dehydrating the gas by heating, chemical addition, solid desiccant and membrane dehydration mitigates these problems and improves safety. GENERON offers the following efficient and cost effective solutions for process gas:

The GENERON® Advantage

- Extensive Experience – custom designed skids

- State-of-the-art Membrane – high recoveries

- Simple Solution – no moving parts, minimal maintenance

- Engineering support from concept to completion

- Remote Operation – Minimal attention required, fully automated systems

- Minimal Losses – low HC losses

- No Chemicals – environmentally friendly

- Small Footprint – easily meet footprint requirements

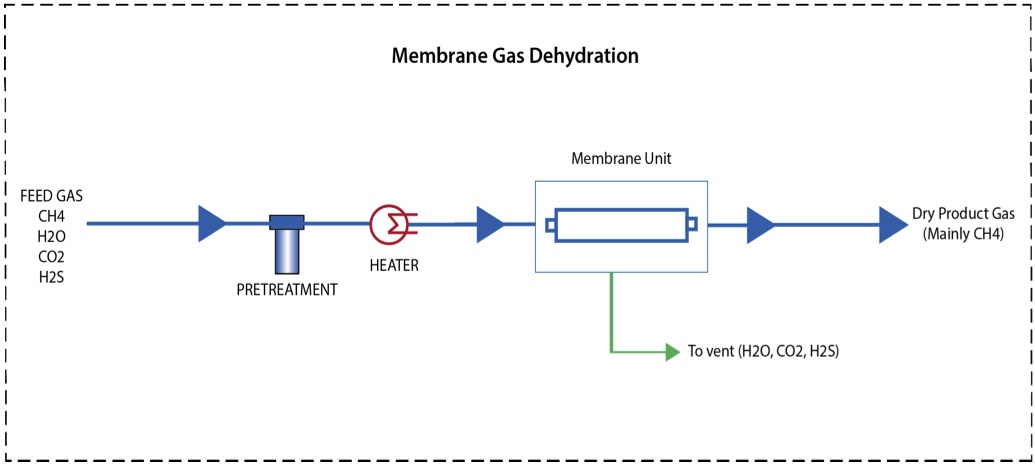

Membrane Dehydration

In GENERON® membrane gas dehydration systems, the feed gas is filtered to remove any trapped liquids and aerosols. The gas then enters the GENERON® membrane filters, where the H2O, CO2 and H2S permeate through the membrane. The non-permeated gas, mainly CH4, remains at process pressure and becomes the product gas.

Membrane Dehydration

- Ideal pressure up to 500 psig (34.5 barg)

- Ideal Temperature: < 160°F / 71°C

- Flow Rate: 0.01 to 10 MMSCFD

- Dew Points down to -40°F / -40°C

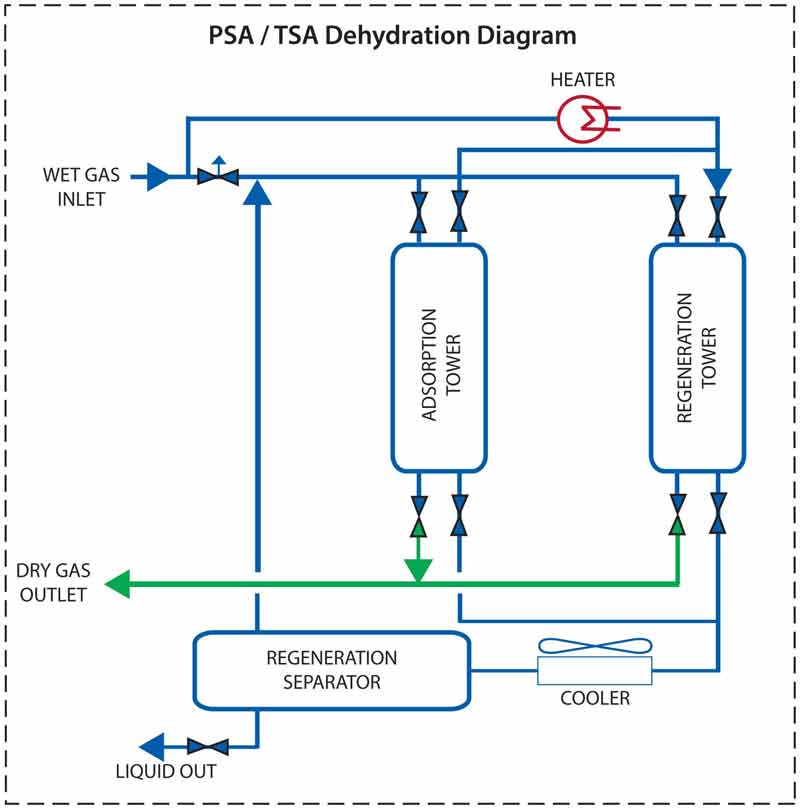

PSA/TSA Dehydration

There are several solid desiccants that possess the physical characteristics to adsorb water from natural gas. These desiccants generally are used in dehydration systems consisting of two or more towers, and utilize regeneration equipment. One tower is on-stream, adsorbing water from the gas, while other tower is being regenerated and cooled. The towers are switched just be-fore the on-stream tower becomes water saturated.

PSA/TSA Dehydration

- Ideal Pressure: 100 – 400 PSIA

- Ideal Temperature: < 110°F

- Flow Rate: < 20 MMSCFD

GENERON facilities are ISO 9000 Certified and follow NEC/CEC (USA & Canada), ATEX (Europe), AS/NZS (Australia), ICECx (Worldwide) explosion protection requirements. Our ASME vessel shop builds all our columns and separators in-house which allows single source accountability.