Compressed Air Drying

As a world leader in membrane and adsorption technology, GENERON provides a full range of Instrument Air Packages to its clients. These packages can be utilized with Primary Air Compression to reduce the overall system size, as well as installation cost and time.

Complimentary to our compression packages, GENERON offers two different types of air drying technology for dew point suppression;

Standard systems include available pressure dew points of +40°F (4°C) and -40°F (-40°C); and optimal technologies are available to reduce the dew point to less than –100°F ( -73°C) where desired, and pressures up to 350 psig (24 barg).

GENERON offers a High pressure option, available to 500 psig (35 bargHigh quality components and manufacturing techniques are used to ensure a continuous supply of clean, dry air and reliable operation.

Twin Tower Heatless Desiccant Dryer

GENERON Heatless Desiccant Dryers consist of two towers containing a specialized material that absorbs the water vapor in the saturated compressed air stream. The amount of time that the saturated air remains in contact with the adsorption material dictates the output air dew point (dryness) of the product.

When compressed air enters the GENERON system through coalescing filters, 99.999% of oil, water and liquid contaminates are removed.

The filtered air is then directed by the solid state controller to the on-line tower where saturated air and water vapor adhere to the desiccant in a process called adsorption.

While the active tower dries the incoming air, the off-line tower regenerates by purging the entrained moisture to the atmosphere with a stream of dry air. The dry air flow is directed to exit the system through a dust removal filter, providing a clean & dry air supply into your plant distribution system.

GENERON systems provide moisture free air down to a -40° or -100°F pressure dew point.

FEATURING

- Solid state controller and sensors

- Inlet and discharge filters

- Control air, tower pressure gauges, safety valves

- High performance switching & check valves

- ASME coded vessels

- High humidity & Failure to switch alarm

- Pressure dew points to -100°F

Technical Data

|

Model |

Inlet Air Capacity |

Instrument Air Flow |

Approximate Dimensions in / mm |

|||||||

|

Scfm |

Nm3/m |

Scfm |

Nm3/m |

Width |

Depth |

Height |

||||

|

GTTD 200 |

200 |

5.7 |

170 |

4.8 |

48 |

1229 |

31 |

782 |

86 |

2179 |

|

GTTD 250 |

250 |

7.1 |

213 |

6.0 |

48 |

1229 |

33 |

838 |

86 |

2179 |

|

GTTD 300 |

300 |

8.5 |

255 |

7.2 |

48 |

1229 |

33 |

838 |

86 |

2179 |

|

GTTD 400 |

400 |

11.3 |

340 |

9.6 |

81 |

2068 |

45 |

1145 |

92 |

2347 |

|

GTTD 500 |

510 |

14.4 |

434 |

12.3 |

81 |

2068 |

45 |

1145 |

94 |

2375 |

|

GTTD 600 |

650 |

18.4 |

553 |

15.6 |

81 |

2068 |

45 |

1145 |

95 |

2403 |

|

GTTD 770 |

770 |

21.8 |

655 |

18.5 |

81 |

2068 |

45 |

1145 |

100 |

2453 |

|

GTTD 1000 |

1000 |

28.3 |

850 |

24.1 |

119 |

3108 |

59 |

1509 |

97 |

2459 |

|

GTTD 1200 |

1200 |

34.0 |

1020 |

28.9 |

119 |

3018 |

59 |

1509 |

122 |

3101 |

|

GTTD 1500 |

1500 |

42.5 |

1275 |

36.1 |

125 |

3185 |

73 |

1844 |

110 |

2794 |

|

GTTD 2000 |

2000 |

56.6 |

1700 |

48.1 |

132 |

3353 |

73 |

1844 |

110 |

2794 |

|

GTTD 2600 |

2600 |

73.6 |

2210 |

62.6 |

158 |

4023 |

79 |

2012 |

121 |

3073 |

|

GTTD 3000 |

3000 |

85.0 |

2550 |

72.2 |

158 |

4023 |

79 |

2012 |

121 |

3073 |

|

GTTD 4000 |

4000 |

113.3 |

3400 |

96.3 |

211 |

5364 |

92 |

2347 |

123 |

3129 |

|

GTTD 5000 |

5000 |

141.6 |

4250 |

120.3 |

224 |

5700 |

92 |

2347 |

127 |

3213 |

|

GTTD 6000 |

6000 |

169.9 |

5100 |

144.4 |

224 |

5700 |

92 |

2347 |

125 |

3185 |

Membrane Air Dryers

Using our patented GENERON® Dehydration Membranes, GENERON designs and provides highly compact and virtually maintenance- free Instrument Air Packages.

The GENERON® Membrane Air Dryers are ideal for pressure dew points of 40°F (4.4°C) and point source applications. The membrane dryers are robust and need very little maintenance. They are easily scalable to any size – just add more membranes to increase the capacity!

The compressed air, saturated with water vapor, enters the membrane housing and flows through a bundle of GENERON® hollow-fibers. GENERON® Dehydration Membranes allow the water vapor to pass and separate away from the main air stream, while the air stream remains and is discharged as a dry product. A small fraction of the dry air is redirected internally to sweep the permeated water vapor out of the module through a vent.

GENERON® Membrane Dryers (hyperlink to table 2) perform with the lowest purge-air loss for the highest possible efficiency, saving you time and money in the production process.

FEATURING

- Remote Operation

- Custom Controls and Automation

- Suitable for all Environments

- Factory Testing and On-Site Start-Up Training

- Onshore and Offshore Applications

- Low pressure drop, 2-3 psig

- No CFCs, compressors and heat exchanges to maintain

- No moving parts

- Adjustable dew point to -40°F (-40°C)

- No desiccant replacement required

Technical Data

Examples of Membrane Air Dryer incorporated into primary compression packages:

Twin Tower Heatless Air Dryer

Non-Hazardous area

275 psi (19 barg) Operating Pressure

750 scfm (1200 Nm3/hr) Capacity

-40°F (-40°C) Pressure Dew Point

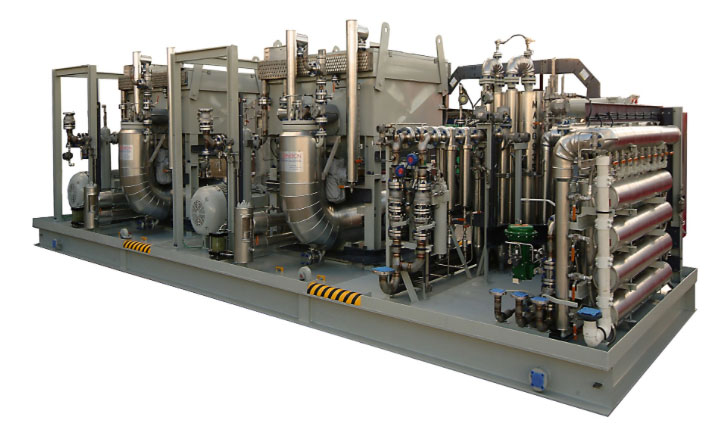

Oil & Gas Applications – Mobile unit designed and manufactured for a major oilfield services company

Non-Hazardous Area classification

Dual-Service and Application Rated

5000 scfm (7900 Nm3/hr) Capacity

100 psig (7 barg) Operating Pressure

-40°F (-40 °C) pressure dew point

-OR-

7900 scfm (12,500 Nm3/hr) Capacity

350 psig (24 barg) Operating Pressure

-100°F (-73°C) pressure dew point

Instrument Air System for Marine and Offshore Application

Class I Div 2 Area classification

1100 scfm (1750 Nm3/hr) Capacity

150 psig (10 barg) Operating Pressure

-40°F (-40°C) Pressure Dew Point

Instrument Air Package with integrated Compressor, Air Receiver, and Dry Air storage vessel

ATEX classification, CE/ PED

315 scfm (500 Nm3/hr) Capacity

150 psig (10 barg) Pressure

-40°F (-40°C) pressure dew point

Instrument Air Package for Offshore

Class I, Div 2 – T3 Area Classification

120 scfm (190 Nm3/hr) Capacity

175 psig (12 barg) Pressure

-40°F (-40°C) dew point product

Customized Hazardous Area Package for Offshore

ATEX certified, CE/ PED marked, includes GENERON® Compressors, GENERON® Patented Dehydration Membranes, and GENERON® patented Nitrogen Membrane Modules.