Modular PSA Nitrogen Generator

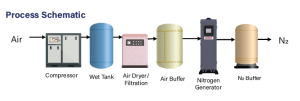

GENERON’s patent pending Modular PSA Nitrogen Generators separate nitrogen from compressed air utilizing Pressure Swing Adsorption (PSA) technologies. Factory generated nitrogen production eliminates the safety issues of handling and storing bottles and liquid nitrogen. The GENERON® Modular PSA is manufactured in the USA. It is machined from heavy duty aluminum components. It has an integrated manifold design eliminating cumbersome piping which eliminates potential leaking and generates more product. The GENERON® Modular PSA Nitrogen Generator can be built with up to 5 banks deep.

Typical Applications:

- Food and Beverage

- Pharmaceutical Industry

- Oil/Gas and Chemical Industries

- Metals / Laser Cutting

- Plastic Injection Molding

- Laboratory

- Electronics / Semiconductor manufacturing

- Tire Industry (Manufacture and Mounting)

- Autoclave Applications

- Medical Industry

Features:

- Made in the USA

- Compact Design

- Flexible Modular Design

- Fully Automatic Unattended Operation

- Manifold Control Block

- Internal Diagnostics

- Low Energy Consumption

- Simple Maintenance

- Long Life Zirconium Oxide Sensor

- Factory Pre-Tested

- Multiple Design Sizes

Benefits:

- Field Expandable (allows for adding additional banks to a generator)

- Multiple NG series generators can be operated together

- Small Footprint with two standard sizes

- PLC with HMI Color Touch Screen Controller, Factory Programmed, Password Protected

- No cumbersome pipe work with multiple leak point potential

- With removal of unnecessary piping, nitrogen ratio to compressed air increases

- Lower operational costs with long life cycling valves

- Increased life of oxygen sensor from 18 months to 60 months

- Unit is pretested and set to your specifications on our certified test stand

- Able to perform an internal testing of all valve seal seating

NG-72″ Series >DOWNLOAD DATA SHEET

| Dimensions: | NG-7-5= 65″L x 24″W x 85″H |

| Weights: | NG-7: 3,350lbs (1,520) with Carbon Molecular Sieve |

| Inlet Air Connection: | 1″ Female NPT |

| Nitrogen Outlet Connections: | 3/4″ Female NPT |

| Max Temperature: | 50°-140°F (10°-60°) |

| Max Pressure: | 90-150psig (6.2-10.3barg) |

| Power: | 120 volt single phase 1/2 kW |

*Flow values, sizes and weights are nominal

| Nitrogen Purity / Flow Rate (SCFH) | |||||||

| Model | 95% | 97% | 99% | 99.5% | 99.9% | 99.99% | 99.999% |

| NG 7-1 | 1,486 | 1,229 | 889 | 767 | 486 | 292 | 124 |

| NG 7-2 | 2,971 | 2,458 | 1,777 | 1,534 | 972 | 583 | 248 |

| NG 7-3 | 4,457 | 3,687 | 2,666 | 2,301 | 1,459 | 875 | 373 |

| NG 7-4 | 5,942 | 4,916 | 3,555 | 3,068 | 1,945 | 1,166 | 497 |

| NG 7-5 | 7,428 | 6,145 | 4,443 | 3,835 | 2,431 | 1,458 | 621 |

| Performance data is based on inlet air at 110psig and 80 °F. Flow values are averages throughout a cycle with tolerances of ±3%. | |||||||