Hydrogen Recovery Packages

The demand for cleaner and higher-value fuels, chemical products and production of electronics are growing worldwide due to the increased use of hydro-treating and hydro-cracking. The processes used for generating hydrogen typically create residual gas streams or by-products, that still contain a significant amount of valuable pressurized hydrogen.

Alternate technologies to recover and purify hydrogen rich gas streams include PSA (pressure swing adsorption) technology. GENERON® PSA technology is used when ultra-pure hydrogen (99.9% to 99.999+%) is required. GENERON® membrane filters are applied to more economically recover hydrogen from hydrogen rich gas streams with minimal losses of 1 to 10% of your valuable hydrogen. Using GENERON® membrane filters in such separations will achieve hydrogen product purities from 90 to 99.9%.

GENERON® membrane filters are applied to economically recover hydrogen from gas streams with only 1 to 10% of your valuable hydrogen. Using GENERON® membrane filters will deliver hydrogen product purities from 90 to 99.9%.

The GENERON® Advantage

- Extensive Experience – custom designed skids

- State-of-the-art Membrane – high recoveries

- Engineering support from concept to completion

- Simple Solution – no moving parts, minimal maintenance

- Remote Operation – Minimal attention required, fully automated systems

- Minimal Losses – low H losses

- No Chemicals – environmentally friendly

- Small Footprint – easily meet footprint requirements

Typical Applications:

Typical Applications:

- Amine Production off-gas

- Ammonia purge gas

- CO purification

- Cold box down-stream

- Desulphurization purge gas

- FCC overhead gas

- Gas-to-liquid fuel production

- H2 PSA purge gas

- H2:CO ratio adjustment in syngas

- Hydro-cracker purge

- Methanol production

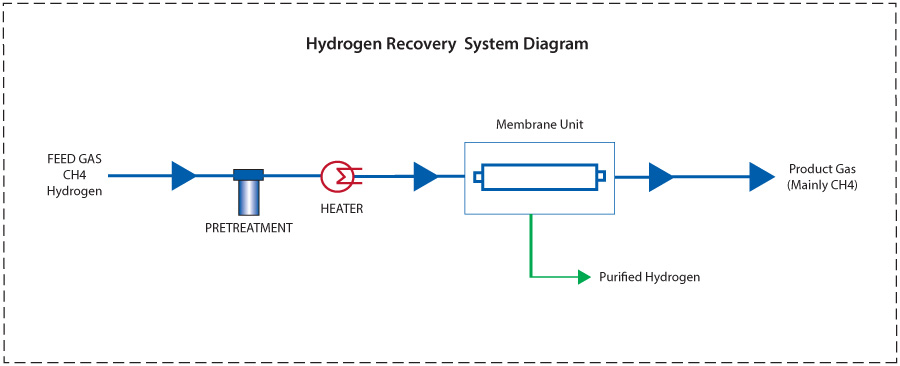

In a GENERON® membrane system for hydrogen recovery, the feed gas is cooled to remove the higher hydro-carbons that condense inside the membrane fibers during the separation process. After subsequent particle and condensate removal steps, the feed gas is then heated to an optimum operation temperature and ready to enter the GENERON®membrane filters. Hydrogen gas permeates through the membrane walls. The permeated gas becomes a purified hydrogen product. The “slower” permeating gases are collected in the non-permeate (“retentate”).

SYSTEM PERFORMANCE

SYSTEM PERFORMANCE

- Feed gas pressures up to 1,000 psig (69 barg)

- 90%-99% Hydrogen Recovery

- Purities to 99.9%

- 99.9%-99.999+% with PSA technology

- Flow rates from 0.01 to 100 MMscfd

- Lower maintenance cost

SYSTEM PERFORMANCE

SYSTEM PERFORMANCE