Safer Flights with Aircraft Nitrogen Generating Systems for Fuel Tanks

August 20, 2019

Safety and reliability of aircraft components and systems are critical in the aviation industry. Fires are hazardous in all sections of an aircraft, particularly in tanks containing jet fuel.

The catastrophic TWA Flight 800 accident of 1996, which killed all 230 passengers including service crew, was linked to an electric spark in one of the Boeing 747’s fuel tanks which caused an explosion when it contacted fuel vapor and air.

To minimize the likelihood of fires occurring in the fuel tanks of aircraft, the Federal Aviation Administration (FAA) has mandated aircraft manufacturers to minimize the flammability exposure of gases in the tanks using fuel inerting systems.

Fuel inerting is the process of preventing combustion in a confined space using a chemically unreactive substance. A good example of an inert gas is Nitrogen.

What Is an Aviation NGS?

Aviation nitrogen generation systems (NGS) are the equipment used to generate pure nitrogen or nitrogen-rich air which helps to reduce the flammability of the void above jet fuel in aircraft fuel tanks. NGS for aircraft can be portable, skid-mounted, or wall-mounted equipment adaptable to space-constrained applications. How these systems prevent combustion is correlated to a basic concept of firefighting known as the ‘Fire Triangle.’

A fire triangle diagram depicts the three elements that must be in place for a fire to occur – a source of fuel, heat, and oxygen (air). If we take out any element of the fire triangle, it would douse a fire, or prevent it from occurring in the first place.

Nitrogen acts as an inert gas at room temperature which is denser than oxygen. Aircraft fuel inerting systems work by using nitrogen to displace oxygen in the aircraft’s fuel tank, otherwise known as nitrogen purging. A low concentration of oxygen in the tank helps to prevent explosions.

How Do Aircraft Fuel Inerting Systems Work?

The FAA has studied several methods for reducing the flammability exposure of commercial aircraft. However, one technique has been developed and analyzed extensively – integrating Air Separation Modules (ASMs) in the fuel tanks.

In conjunction with some leading aircraft manufacturers, it designed an onboard inert gas generation system (OBIGGS) comprising ASMs that utilized aircraft bleed air (compressed air coming from the compressor stage of the aircraft which is used to pressurize the cabin) to generate nitrogen-enriched air (NEA). The NEA was then used to displace enough oxygen to keep its concentration levels at below 12% to prevent combustion in the fuel tanks.

How On-site Nitrogen Generators Work

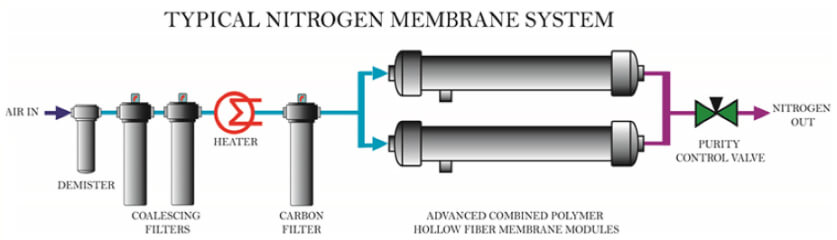

On-site nitrogen generators separate the gas from atmospheric air. Dry, compressed air enters the system through an intake and is screened using a carbon molecular sieve (CMS) or polymeric hollow fiber membrane (HFM) housed within a cylindrical vessel.

These media are semi-permeable barriers with high selectivity (for membrane systems, the efficiency of separation and resulting purity of nitrogen gas depends on the pore size of the membrane).

The CMS or membrane separates oxygen, rare gases, and air-borne impurities from the air stream, allowing pure, dry nitrogen to pass through. Most NGS and membrane nitrogen generators can generate nitrogen gas of up to 99% purity.

5 Benefits of Onboard Inert Gas Generation Systems

Using NGS in an aircraft has significant advantages to manufacturers and airline operators.

1. Cost-effective

Since the raw material is air, these systems produce nitrogen gas cost-efficiently, ensuring a reliable supply of nitrogen at the point of use.

GENERON offers a range of options to reduce your total cost of ownership on nitrogen generation systems.

2. Efficient

Aircraft NGS system can generate nitrogen gas devoid of impurities and water vapor. The GENERON® Nitrogen on Wall (NOW) systems are lightweight, low-profile NGS aviation systems capable of producing N2 of up to 99.99% purity. These wall-mount nitrogen generators allow for convenient wall mounting, while custom solutions can be defined per the client’s specifications.

3. Safe

On-site NGS generates nitrogen gas for immediate use without storing it. This eliminates the need for temporary storage in high-pressure cylinders or tanks which are bulky and vulnerable to leaks. Since nitrogen gas can displace oxygen, it could cause asphyxiation (oxygen deprivation) in confined spaces such as aircraft cabins during an accident.

4. Reliable

Aircraft NGS systems have longer service lifetimes with automated operation. Also, the cost of maintenance is generally lower than conventional solutions, with part replacements seldom required.

5. Eco-friendly

Liquefying or compressing nitrogen into cylinders for sale – the conventional means of providing nitrogen in industries – is an energy-intensive process that has adverse effects on the environment.

On-site nitrogen generation systems provide power savings for industrial users as there is no requirement to run large chillers and compression units. Low-power operation and non-hazardous storage reduce toxic emissions.

Contact GENERON for All Your Nitrogen Generation Needs!

GENERON is a world-class manufacturer of nitrogen generation systems, with 40+ years of experience and thousands of equipment deployed worldwide. We offer customized fuel inerting systems for commercial and military aircraft at our ISO 9001 certified facilities in Houston and California.

Our staff engineers can provide more information about our products and consultations for onboard inert gas generation systems. Contact us online today!