Oxygen vs. Nitrogen Laser Cutting: Which is Better?

November 09, 2018

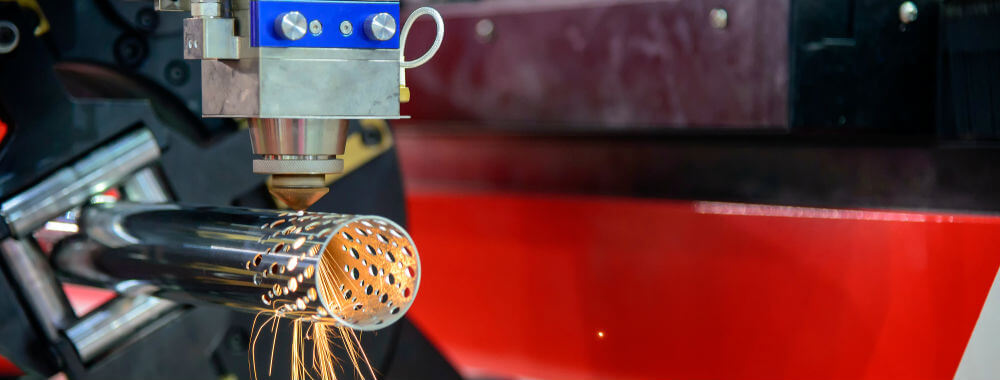

Laser cutting can only produce a clean edge if you use an assist gas to blow away molten material. Traditionally, oxygen has been the gas used, but nitrogen offers many advantages for cutting steel.

Explore the benefits of nitrogen cutting when working with mild steel, stainless steel, and aluminum.

What is Nitrogen Cutting?

Nitrogen is an inert gas. It does not react with the molten metal, even when the laser heats the surface to high temperatures. Its purpose in laser cutting is to exclude oxygen from the cutting zone, preventing the metal from oxidizing or discoloring. The result is a clean edge that does not require any cleaning up after the cutting is complete.

Laser Cutting: Oxygen vs. Nitrogen

Oxygen performs a very different role in laser cutting. Whereas nitrogen ensures no reaction takes place at the cutting site, oxygen reacts with the metal in an exothermic reaction. That means more heat is produced around the cutting site, speeding up the cutting process.

The downside is that oxidation causes damage to the cut edge, which means a further clean-up process is required. You can use manual grinding, chemical removal, or other methods to finish the edge. In contrast, nitrogen cutting produces a clean edge.

Applications for Nitrogen-Assisted Laser Cutting

Nitrogen-assisted laser cutting is suitable for a wide range of applications. Here are some situations in which you can use laser cutting with a nitrogen generator, such as GENERON’s compact nitrogen generators.

Plasma Cutting Stainless Steel with Nitrogen

Many manufacturers prefer to use plasma cutting with nitrogen when working with stainless steel. This is because when it comes to laser cutting, nitrogen produces a much cleaner edge than oxygen. As a result, nitrogen cutting can help you save money on finishing processes, which can require machinery that is expensive to purchase and maintain.

Laser Cutting Mild Steel with Nitrogen

Nitrogen laser cutting is suitable for shaping mild steel, although other factors affect the decision. Using nitrogen provides the most benefit when you are cutting very thin material. If the steel is thicker than 1/8 in, cutting speed is similar for both nitrogen and oxygen.

Depending on the gas delivery method used, nitrogen cutting can be more expensive per hour than oxygen, so you might find it more cost-effective to use oxygen if you are cutting very thick steel.

Plasma Cutting Aluminum with Nitrogen

Using nitrogen can produce excellent edge quality when cutting aluminum. By reducing oxidation by using nitrogen when cutting aluminum, you can reduce the costs of processes the metal after cutting to improve edge quality. Take a look at nitrogen generators for metal-working applications from GENERON to take your aluminum cutting to the next level.

Why Use a Nitrogen Generator for Laser Cutting?

Using a nitrogen generator for laser cutting is an excellent way to reduce costs. Regularly ordering nitrogen containers is not only inconvenient, but also expensive. For convenient and efficient laser cutting with nitrogen, check out GENERON’s selection of wall-mounted nitrogen generators.

Contact GENERON today to find out more about our nitrogen gas systems and find the option that is right for your business.